1.The heat engine: Q → W

In this heat engine, heat Q is added to the system and

work W is done by the system. This transformation of

energy Q → W can be in the opposite sense W → Q

which is the process we find when friction occurs or in a

refrigerator.

In this heat engine, heat Q is added to the system and

work W is done by the system. This transformation of

energy Q → W can be in the opposite sense W → Q

which is the process we find when friction occurs or in a

refrigerator.

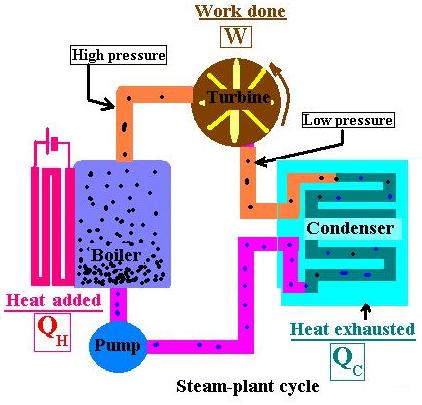

The temperature is the same as the surroundings, the gas expands isothermally

as the volume of the gas increases, it does work on the turbine. The gas is

ideal and the process is isotherm then &the temperature remains constant in

the boiler.

During a cycle, then Delta;U = 0, W = QH - QC according

to the first law. QH - QC represents the net heat added to the

system during the entire cycle.

If QC is null, that is no heat is exhausted, the gas after work will

return to the boiler with no need to heat again. Therefore the gas remains stationnary

in the circuit.

But we need to have a cycle in order make the engine morking for a long time, that is

to compress again the liquid at low pressure. The solution consistts of setting a

condensor between the turbine and the pump. In this case, heat is extracted from the

working substance toward the environment. Once the liquid arrives in the boiler, it

is heated again, then compressed and the cycle is maintained. The engine works.

Here are the four steps:

- The boiler heat water until evaporation. Its temperature increases, so is its pressure,

- At a certain point, the vapor expands and does work by hitting the turbine blades,

- The vapor, at lower pressure, travels through the circuit and heat is exhausted from the condenser,

- The pump absorbs the liquid into the high-pressure boiler and the cycle starts again.

Heat was converted to work. This is how it operates the device called heat engine

The efficiency of the engine is defined as the ratio of the input energy to the

output energy for each cycle; that is:

η = W/QH = 1 - QC/QH

In general, the efficienty is equal at most to 40% ( 60% of heat is

wasted). There is no 100% engine; that is QC = 0 and η = 1. All the attempts

for this goal have failed.

There exists no cycle which extracts heat from a

reservoir at a single temperature and

completly converts it into work.

That is the Kelvin-Planck statement of the second law

of Thermodynamics. In other words, It is impossible to have a cycle with no heat exhausted at

low temperature. Recall that we need low temperature at the end of the cycle in order to restart

the cycle.

2.The refrigerator: W → Q

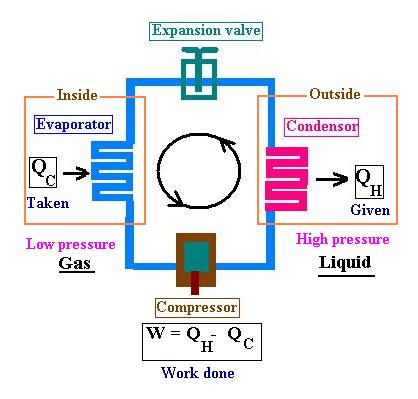

We have four major parts:

- an evaporator,

- a compressor,

- a condenser, and

- an expansion valve.

In the evaporator section, a refrigerant (the working substance) is colder that

the inside of the refrigerator, then It extracts heat from it and becomes vaporized;

changing its phase from liquid to gas.

During the next stage, a compressor(electric motor running a small piston)

compresses (pressurizes)the refrigerant vapor which becomes liquid.

This heated and pressurized liquid refregirant travels through the condenser (coil

outside the refrigerator)and gives off a part of its heat absorbed by the air around it.

Its temperature decreases.

The liquid flows through the expansion valve (using the throlling process). After passing

this valve, the pressure and the temperature of the refrigerant is reduced. The liquid

will reach the evaporator at a certain temperature.

If this temperature is not reached yet, the cycle will continue until it is done.

We define the coefficient of performance for a refrigerator as the ration

of heat extracted from the inside to the work done (by the electric motor of the

compressor; that is:

κ = QC/W

The heat pump like refrigerator as well as a freezer or an air conditioner is a system that

transfers heat from the evaporator section (inside the refrigerator), to the

condenser section (outside the refrigerator), by pumping (compressing) the

refrigerant continuously through the circuit. The system is used as cooling, but in the

reverse, it could be used as heating relatively to outside or inside space.

Using a thermocouple (thermometer), when the desired temperature is reached,

the Compressor (or pump) stops and so does the heat transfer.

To maintain -20 F (-29 C), as with a frozen food freezer, Freon-12 must

maintain a pressure of 15.3 pounds per square inch in the evaporator section.

Currently, we use the Ammonia (NH3)for the working substance instead of the

Chloro-Flouro- Carbon or CFC (brand name: Freon ). It boils at - 6.5 C (about 20 F).